IMPROVING YOUR PRODUCT QUALITY

CONSULTANCY FOR THE SETTING OF A COMPANY MANAGEMENT SYSTEM

Prolab offers the consultancy service for setting up the corporate quality management system according to the standards:

- ISO 9001: requirements of a quality management system for an organization. The requirements expressed are of a general nature and can be implemented by any type of organization

- ISO 13485: "Medical devices - Quality management systems - Requirements for regulatory purposes" identifies a standard for the quality management system specific for companies in the medical sector , which includes aspects of the ISO 9001 standard and specific requirements for the medical device industry.

- ISO / IEC 17025: is a standard that expresses the "General requirements for the competence of testing and calibration laboratories"

- ISO 45001: "Occupational health and safety management systems - Requirements with guidance for use", is an international standard that specifies the requirements for a system management of health and safety at work and provides guidance for its use, to enable organizations to provide safe and healthy jobs by preventing accidents at work and health problems, as well as by improving OSH proactively.

- ISO 14001: environmental management standard (EMS) which establishes the requirements of an "environmental management system" of any organization and is part of the ISO 14000 series developed by the "ISO / TC 207".

- EN ISO / IEC 80079-34: Application of quality management systems for the manufacture of equipment operating in a potentially explosive area "ATEX"

The setting and certification of the Quality Management System aims to:

- Facilitating the diffusion of quality culture in the company;

- Make staff at all levels more sensitive, aware and motivated;

- Create a new mentality oriented towards improvement;

- To lead to a better rationalization of the organization and information flows;

- Increase the effectiveness and efficiency of business processes;

- Allow to reduce the costs of "non-quality";

- Allow to improve relations with customers and suppliers;

- Induce a return in terms of image to customers;

- Allow to meet the needs expressed or implied by its customers;

- Make available an effective promotional tool to increase sales or extend penetration into new markets and meet the requirements of current legislation

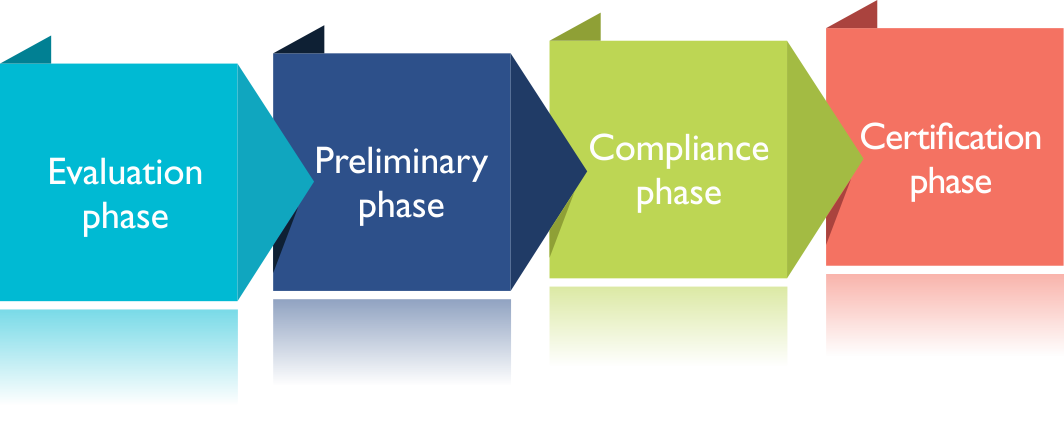

The certification process can be described as follows:

Evaluation phase

- Comparison between quality system and standard requirements

- Process analysis

- Determination of needs

Preliminary phase

- Training

- Acquisition of culture

- Management commitment

Compliance phase

- Implementation of the corrective action plan

- Adjustment of the quality system documents

- Adaptation of the quality manual

- Conduct of internal inspections

Certification phase

- Sending the manual to the certification body

- Possible interventions following the document analysis

- Choice of date for the visit

- Preparation of the location for the visit

- Performing the visit

- Arrangement of detected non-conformities

- Obtaining certification